The engraving was done by a buddy of mine who has a laser engraver. He may be moving out of state next summer so i could be loosing that source. Working on some other ideas as to dress them up a bit. I wondered if the magnets were overkill also. They are 3/16" so there are pretty small, you could probably get by with just one set but its nice and solid. I would be willing to post pictures of the stages on the build up these boxes if anyone is interested. I was able to crank out 6 boxes in one day, less the finish time.

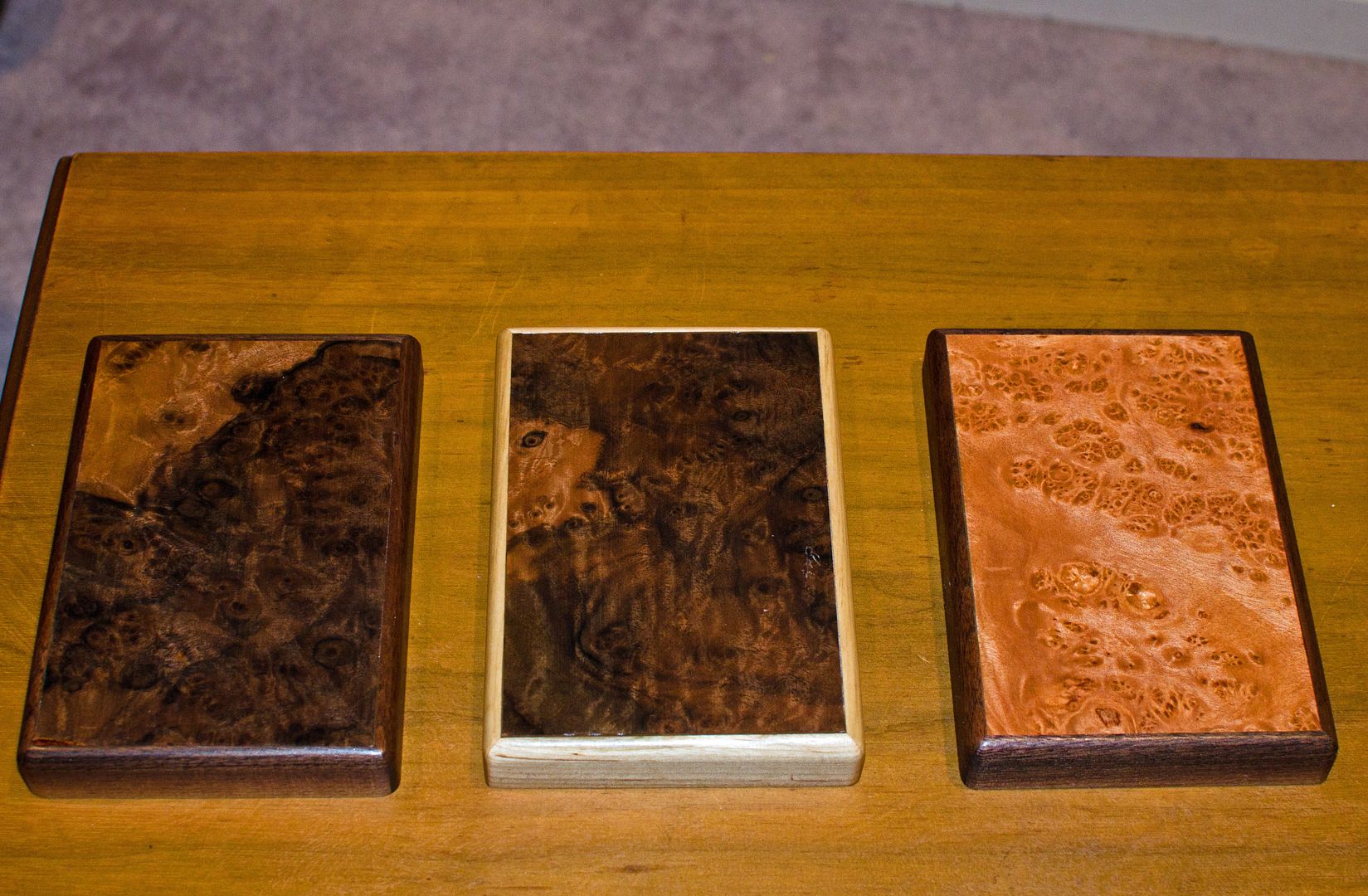

Nice boxes Jay Bird. The wood you are using is amazing, is it local ?

Reply With Quote

Reply With Quote

Bookmarks